Cofferdam – Types of Cofferdam

A cofferdam may be defined as a temporary structure that is constructed on a river or a lake or any other water-bearing surface for excluding water from a given site to execute the building operation to be performed on dry surface. The walls of the temporary structure should be practically water tight or at least they should be able to exclude water to such an extent that the quantity of water that leaks inside the enclosed area, can be easily pumped out. Cofferdams are classified according to the type of construction. The type of construction is dependent upon the depth, soil conditions,, fluctuations in the water level, availability of material etc. Cofferdams are advantageously constructed where a large area of site is to be enclosed and the hard bed is at reasonable depth.

Considering the material used in their construction, cofferdams may be divided into the following categories.

(a) Earthen cofferdam

(b) Rock-fill cofferdam

(c) Single-walled cofferdam

(d) Double-walled cofferdam

(e) Crib cofferdam

(f) Cellular cofferdam (Circular or diaphragm type)

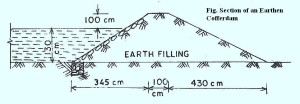

(a) Earthen cofferdam:

It essentially consists of an earthen embankment built around the area to be enclosed. It is constructed in places where the depth of water is not much, say 13 to 18 in. and the velocity of the current is very low. As a precautionary measure, the earth bank is carried about one metre above the water level. The top width of the bank should not be less than 1 in. and the side slopes in a vary from 1 : 1 to 1 : 2. The earth embankment should be built from a mixture of clay and sand or clay and gravel. If the estimated quantity of clay is not easily obtainable, the banks may be constructed with a central clay wall with slopes of sand on either side. In order to prevent the embankment from scouring due to the action of water, side slopes of the bank on water side should be pitched with rubble boulders. If the current of water is such that there is a danger of the earthen embankment getting washed away, canvas bags half filled with material of embankment (mixture of clay, sand or gravel) are stacked one over the other to form the embankment. After the work of construction of cofferdam is over, the water from the enclosed area is pumped out so as to leave a dry surface inside. Excavations can then be performed to the required depth and the work of construction of foundations carried out.

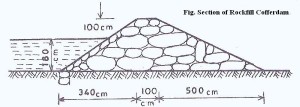

(b) Rock-fill cofferdam:

If the depth of water to be retained by the embankment of cofferdam is of order of 18 to 3 in., stone or rubble is used for the embankment. This construction is adopted only if the stone is easily available in the nearby areas. The stones are assembled in the required shape of the embankment and the voids are partially filled with earth and stone-chips. The side slope on the water side is protected by pitching.

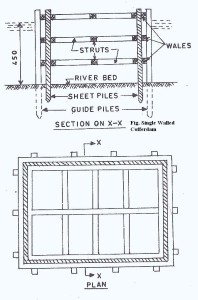

(c) Single-walled cofferdam:

This type of cofferdam is used in places where the area to be enclosed is very small and the depth of water is more, say 4.5 to 6 m Timber piles known as guide piles are first driven deep into the firm ground below the river bed. Depending upon the velocity of the current of the water in the river, the centre to centre spacing of the piles may vary between 1.8 to 4 m. Longitudinal runners called wales are then bolted to the guide piles at suitable distance apart. Steel or wooden sheet piles are then driven into the river bed along the wales and are secured to the wales by bolts. The sheets on the two faces arc braced by trussed arrangement of struts. This helps in increasing the stability of walls against the water pressure. Half-filled bags of sand stacked on the inside and the outside faces of the sheets help in increasing the stability of cofferdam. After the cofferdam is constructed, the water in the enclosed area is pumped out and the construction work is taken up.

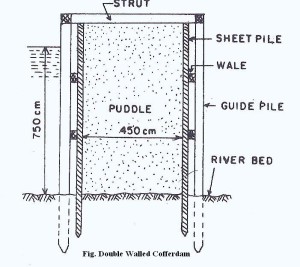

(d) Double-walled cofferdam:

For cofferdams required to enclose larger areas in deep water, single wall type becomes uneconomical as larger sections of trussed struts would be necessary to resist the water pressure. Double-walled cofferdam is provided in such situations. Its construction is essentially the same as that of a single-walled cofferdam except that in place of one wall, a pair of walls with a gap in between is used all along the boundary of the space to be enclosed. This type of cofferdam can be used in depth of water up to 12 m. As the depth of water increases, the wall should be made wider in order to make it stable against over4urning and sliding. The distance between the two walls depends upon the depth of water. The thickness of wall should be equal to the depth of water up to 3 m. For greater depths of water, the thickness of wall should be 3 m. plus ½ the depth of water in excess of 3 m. At their top, the two faces of the walls are connected by steel rods spaced at close intervals. To prevent the leakage from the ground below, the sheet piles are driven to a good depth in the bed.

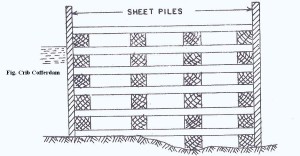

(e) Crib cofferdam:

In deep waters where it is difficult to penetrate the guide piles or sheet piles into the hard bed below, crib cofferdam is used. In this type of construction, the sheet piles are supported by a series of wooden cribs. A crib is a framework of horizontal timbers installed in alternate courses to form pockets which can be filled with earth or stones. The length and breadth of each crib depend upon the depth of water and the current of flow. The framework of the cofferdam (made from, logs of wood) is prepared on ground and then floated to the site where the cofferdam is to be constructed. The layers of sand and the other loose material overlying the impervious hard bed is dredged out. Crib is then sunk to the position, the bottom of each crib is given a shape to fit in the variation in the surface of bed rock. The space inside the crib is then filled with stone or any other material, so as to make it stable against sliding and overturning. Timber or steel sheet piles are then driven around the crib.

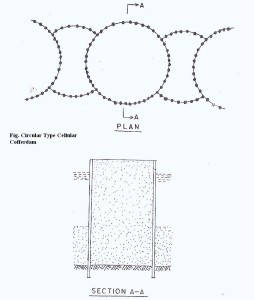

(f ) Cellular cofferdam:

This type of cofferdam is mostly used for de-watering large areas in places where the depth of water may be of the order of 18 to 21 m. Cellular cofferdams are mostly used during the construction of marine structures like dams, locks, whares etc. Cellular cofferdam is made by driving straight web steel sheet piles, arranged to from a series of inter-connected cells. The cells are constructed in various shapes and styles to suit the requirements of site. Finally the cells are filled with clay, sand or gravel to make them stable against the various forces to which they are likely to be subjected to. The two common shapes of the cellular cofferdam are,

(i) Circular type cellular cofferdam.

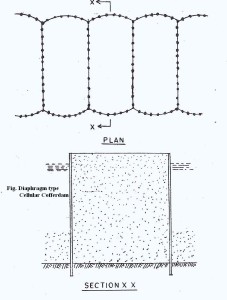

(ii) Diaphragm type cellular cofferdam.

(i) Circular type cellular cofferdam:

The circular type of cellular cofferdam has the advantage that each cell may be filled completely to the top before starting the construction of the next cell without causing any distortion to the shell of the cofferdam, Thus, when one cell is completely filled up it can be used for placing crane or other equipment required for the construction of other cells. In addition, each cell acts as a self-supporting independent unit and in case one of the cells collapses due to scour or interlock damage or some other reason, it does not produce any adverse effect on the neighbouring cells it is found that the interlock stresses reach their maximum permissible value when the diameter of cell is about 21 meter. Hence in case, from design consideration it is necessary to have effective width of the cofferdam more than 21 meter, diaphragm type of cofferdam must be used.

(ii) Diaphragm type cellular cofferdam:

This Consists of a series of diaphragm of steel sheet piles connected as shown in the image below. The straight diaphragm wails are connected to each other by steel piles arranged in the form of arches on either sides. The radius of the connecting arcs is generally made equal to the distance between the straight diaphragm walls. With this arrangement, the tension in the arcs and cross wails remain equal. After the cells are driven to the required depth, they are filled with earth, sand, gravel or other filling material. In this type of cofferdam, as the diaphragm which separates the two cells is a straight wall, it is necessary to fill adjacent cells at approximately the same rate. If this is not done, the unbalanced pressure from the fill will distort the diaphragm (cross-walls) which may result in the failure of the interlocks. In this respect, the circular type cofferdam has the advantage over the diaphragm type cofferdam because in the former, it is not necessary to fill the adjacent cells at the same time. This type of cofferdam has the advantage that the effective width of the cofferdam can be increased to desirable limits without increasing the interlock stresses.

Verү nice article, totally what I was looking for.