Excavation of Foundation in Water Logged Sites

Excavation of foundation in water logged sites poses a great problem for the site engineer. There are various methods of dealing with the situation which depend upon the depth of excavation, depth of water table and many other factors. Following methods are generally adopted while digging foundation trenches in water-logged sites.

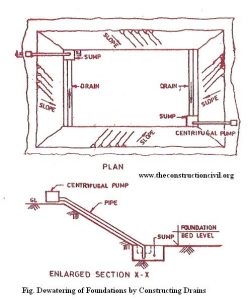

(1) By constructing drains:

This method is generally adopted in shallow foundations in water-logged ground. In this method, drains of suitable size are constructed by the sides of the foundation trench. The drains collect sub-soil water from the sides and the enclosed area and convey it into a shallow pit or sump well. From the sump, the water is continuously bailed or pumped out. This is the cheapest method of draining excavated area and can be easily adopted by deploying unskilled labour and by using simple equipment.

(2) By constructing deep wells:

In coarse soils, porous rock or in sites where large quantity of sub-soil water is required to he drained out, 30 to 60cm diameter wells are sometimes constructed at 6 to 15 m centres all round the site. for temporary drainage of the ground. The water collected in the wells is pumped out continuously . This method can be adopted for depths of excavation up to 24 m.

(3) Freezing process:

This process is suitable for excavations in water-logged soils like sand, gravel and silt. It is advantageously used for deep excavation such as foundation for bridges etc. specially when excavation is to be made adjacent to an existing structure or near some waterways. The process consists in forming a sort of coffer darn by freezing the soil around the area to be excavated. Freezing pipes encasing smaller diameter inner pipes are sunk about one metre centre to centre along the periphery of the area to be excavated. The layout of the pipes should preferably be such that the area enclosed is circular in plan. Freezing liquid is then supplied to the freezing pipes by refrigeration plant. This makes the ground around the pipes to freeze and form a thick wall of frozen earth around the area to be excavated. This process can be used up to 30 m depth of excavation.

(4) By chemical consolidation of soil:

In this method, the soft water-logged soil is converted into a semi-solid mass by forcing chemicals like silicates of soda and calcium chloride into the soil. This method is used for small works.

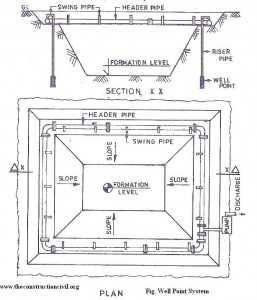

(5) Well point system:

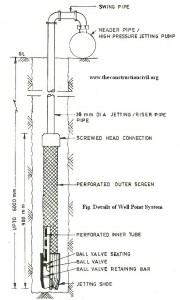

This is a method of keeping an excavated area dy by intercepting the flow of ground water with pipe wells driven deep into the ground. The main components of a well point system are : (i) the well points, (ii) the riser pipe, (iii) the header pipe and (iv) the pumps.

The well point consists of a perforated pipe about 120 cm long and 4 cm in diameter. This pipe has a ball-valve to regulate the flow of water and a screen to prevent the mud from entering into the pipe. The well point tube, is connected to 5 to 75 cm diameter pipe known as riser pipe and is sunk into the ground by jetting.

In the process of jetting, water is forced down through the well point at the rate of 20 to 25 litres per second. The water jet dislodges the surrounding soil and enables the well point to be sunk to the desired depth. After the well point has been sunk to the required depth, the water jet is allowed to run for some time (to ensure washing all sand or silt ‘out of the hole) till the return water from the hole is quite clean. Thereafter the water jet is closed and the annular space formed around the well point (by jetting action of water) is filled with coarse sand and gravel to form a filter zone around the well point. The filter zone prevents the entry of fine particles of the surrounding soil into the well point and avoids clogging of well point screen. The filter sand around the well point should be filled up to water table. The depth of the hole above the water table is filled with tamped clay to act as a clay seal to minimize air getting into the well point through the sand filter.

The well points are suitably spaced (normal spacing being 100 cm c/c) so as to enclose the whole area to be excavated. The riser pipes at their upper ends are connected to a header pipe which in turn is connected to a high capacity suction pump.

After all the well points are installed and connected, the suction pump is put into operation. Due to suction, the ball valve in the well point gets closed and the ground water is drawn in through the well point screen. The water from the well point is sucked up through the riser pipes, flows through the header pipe and is finally discharged away from the site of the work.

This method can be successfully adopted for depth of excavation up to 18 m. Since the suction pump is normally not used to lift water above 6 m depth, in’ deep excavations, where it is necessary to lower water table to a greater depth, multi- stage system of well point is used..

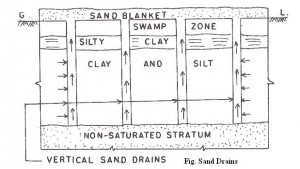

(6) By constructing sand drains:

Sand drains prove very effective in marshy soils. Soil becomes marshy by the process of deposition of thick layers of clays and silts mixed with organic matter by the passage of time. Marshy soil is thus subjected to capillarity and has a high pore water pressure. When this type of soil is subjected to load, its wet soils contents are gradually pushed out on either side and this results in subsidence of the ground. To avoid this, sand drains are made in the ground. The diameter of the sand drains normally varies between 300 mm to 450 mm and their centre to centre spacing may vary from 3 to 6 metre The hole for making the sand drain can be made by driving steel pipe casting into the ground. The drain holes are driven deeper than the marshy layer possibly up to an underlying rock or firm base. The marsh in the pipes is removed by means of jets. Selected type of sand is then filled into the pipes and the pipes are withdrawn leaving vertical sand piles in the ground. A thick layer of sand (sand blanket) is spread over the entire area to be consolidated. When the sand layer is subjected to load, the water from the muck of the marshy soil gets squeezed into the vertical sand drains.

By capillary action, the water from the sand drains rises up and is fed into the sand blanket from where, it can be drained out. The objective of consolidation of soil by this method is to develop increased soil resistance to superimposed loads usually consisting of earth fills in highway or airport construction.

(7) Electro-Osmosis:

Well point system is rendered ineffective in very fine sands, silts or clay, because such soils tend to hold the water by capillary action and offer great resistance to percolation. It has been established that if a direct current is passed through a soil of low permeability, its rate of drainage is greatly increased. In the process of Electro-Osmosis, steel rods forming the positive electrodes are driven in to the soil midway between the well-points, which are made to act as negative electrodes. When electric current is passed, the ground water flows towards the negative electrode (well-points) and is pumped out. This requires very expensive equipment and hence it is rarely used.