Grillage Foundation – Steel & Timber Grillage

Grillage foundation is used when heavy structural loads from columns, piers or stanchions are required to be transferred to a soil of low bearing capacity. Grillage foundation is often found to be lighter and more economical. This avoids deep excavation and provides necessary area at the base to reduce the intensity of pressure within safe bearing capacity of soil. Depending upon the material used in construction of grillage foundation can be broadly divided in the following two categories.

(a) Steel grillage foundation

(b) Timber grillage foundation

(a) Steel grillage foundation:

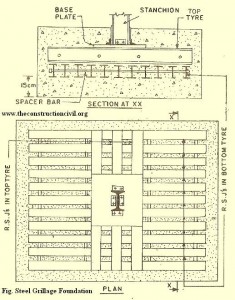

Steel grillage foundation consists of steel beams also known as grillage beams which are provided in single or double tiers. In case of double tier grillage foundation, the top tier is laid at right angles to the bottom one. The grillage beams of each tier are held in position by 20 mm spacer bars with 25 mm diameter pipe separators. The beams are suitably spaced so as to provide facility for the placing and compacting of concrete between them. A minimum clearance of 8 cm is considered most suitable. In any case, the distance between the flanges of the beams should not be more than one and half to two times the flange width with a maximum of 30 cm. If the beams arc spaced more distance apart, there is a danger of the concrete filling not acting monolithically with the beams, and as such, may result in the failure of the foundation. In order to protect the beams against corrosion, a minimum cover of 10 cm is kept on the outer sides of the external beams as well as above the upper flange of the top tier, Cover of concrete under the lower beam should not be less than 15 cm.

Method of construction of Steel Grillage Foundation:

Excavations are carried to the designed depth and the bed is well levelled. This foundation bed is covered with a layer of rich mixture of concrete not less than 15 cm in thickness. This is well compacted so as to make the layer of concrete an impervious bed. Grillage beams of the designed dimensions are then placed on this bed of concrete at specified distance apart using separators. The upper surface of the grillage beam flanges is brought in a horizontal plane and rich cement grout is poured all round the lower flanges of the beams so as to secure the beams to the concrete bed. The concrete is then placed between and around the beams. If another tier is required to be provided. it is kept at right angles to the already laid tier and the entire space is filled with concrete.

(b) Timber grillage:

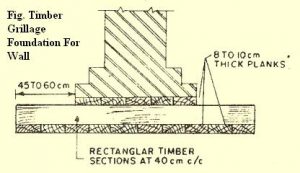

Where the soil encountered is soft and is permanently water-logged building walls can be economically supported by suitably designed timber grillage foundation. Timber grillage foundation can be safely used for light buildings by limiting the loading on the soil to 5.5 tonne/sq.mt. In this type of construction, the concrete block usually provided below the wall footing is replaced by timber platform.

The timber platform consists of planks usually 8 cm to 10 cm. thick, arranged in two layers, one longitudinal and the other across the wall extending beyond the footing base by about 45 cm to6O cm on either side. In the lowermost layers, the planks are 5 cm to 10cm thick depending upon the loading and site conditions. The two layers of planks are separated by rectangular sections of timber spaced at not more than 38cm. centre to centre, the depth of the sections being 0.75 times the width.